Thornshell

Background

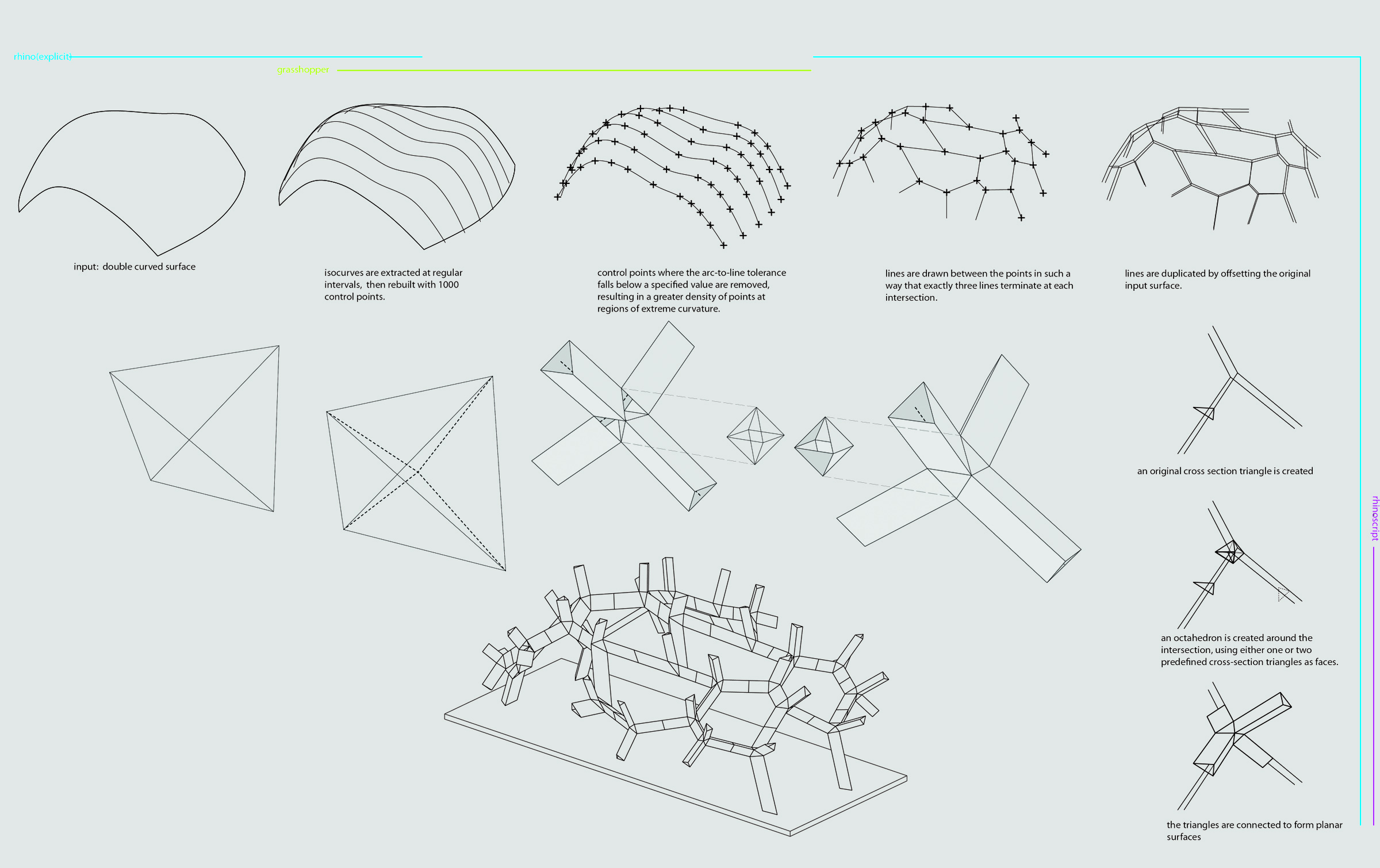

Thornshell is a CAM (computer-aided manufacturing) project uses an algorithmic input surfaces to generate custom nodes for fabrication.

Role

Designer – Team of 3

Tools

Rhinoceros 3D, Grasshopper 3D, MasterCAM X, Flopath, C. R. Onstrud CNC, Adobe Photoshop, Adobe Illustrator

Project Timeframe

3 months

Project context and scope

Thornshell was constructed almost purely through algorithmic equations and material exploration. First, a point field is drawn upon an input surface, where areas of higher curvature retains a higher point density, and low curvature retain low density.

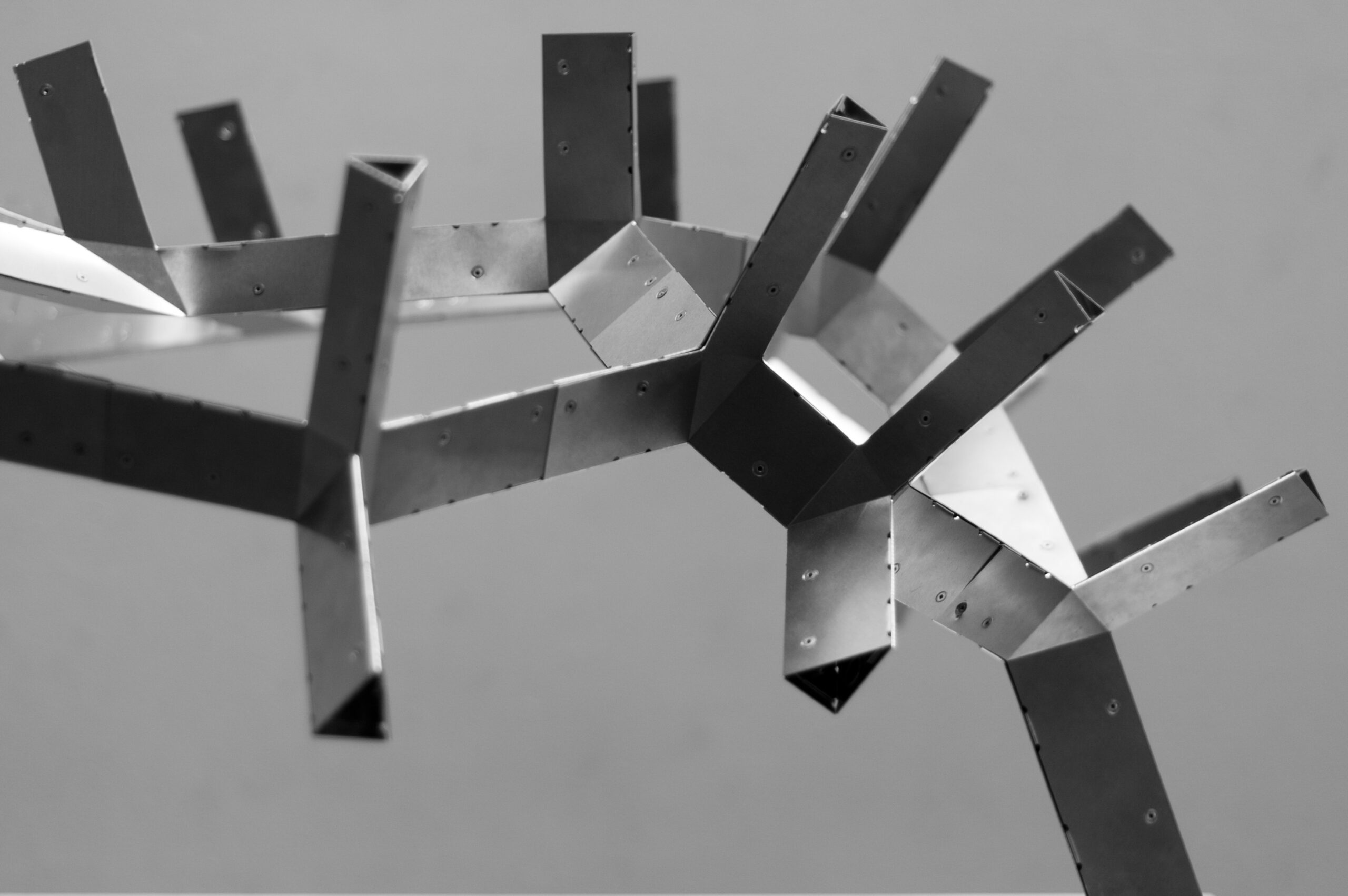

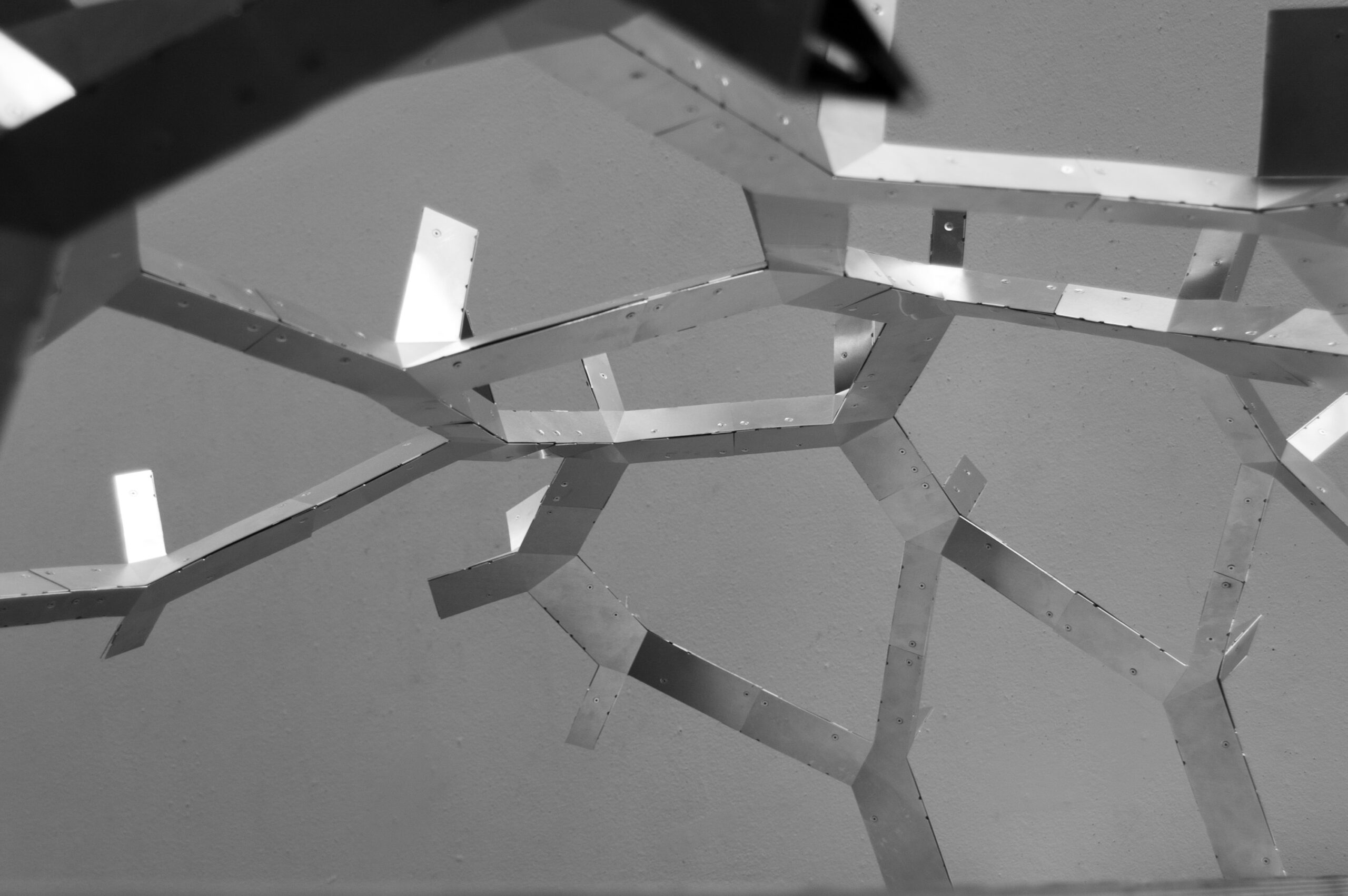

The resulting points are then connected together to form irregular closed hexagons, which are then divided and extruded to form 4-branched ‘tree’ structures, that are then rejoined together to create a new object separate from the starting input.

The resultant form gains self-authorship through its own logic of aggregation, parametric relationships, inherent geometric constraints, and material conditions.

Project Construction

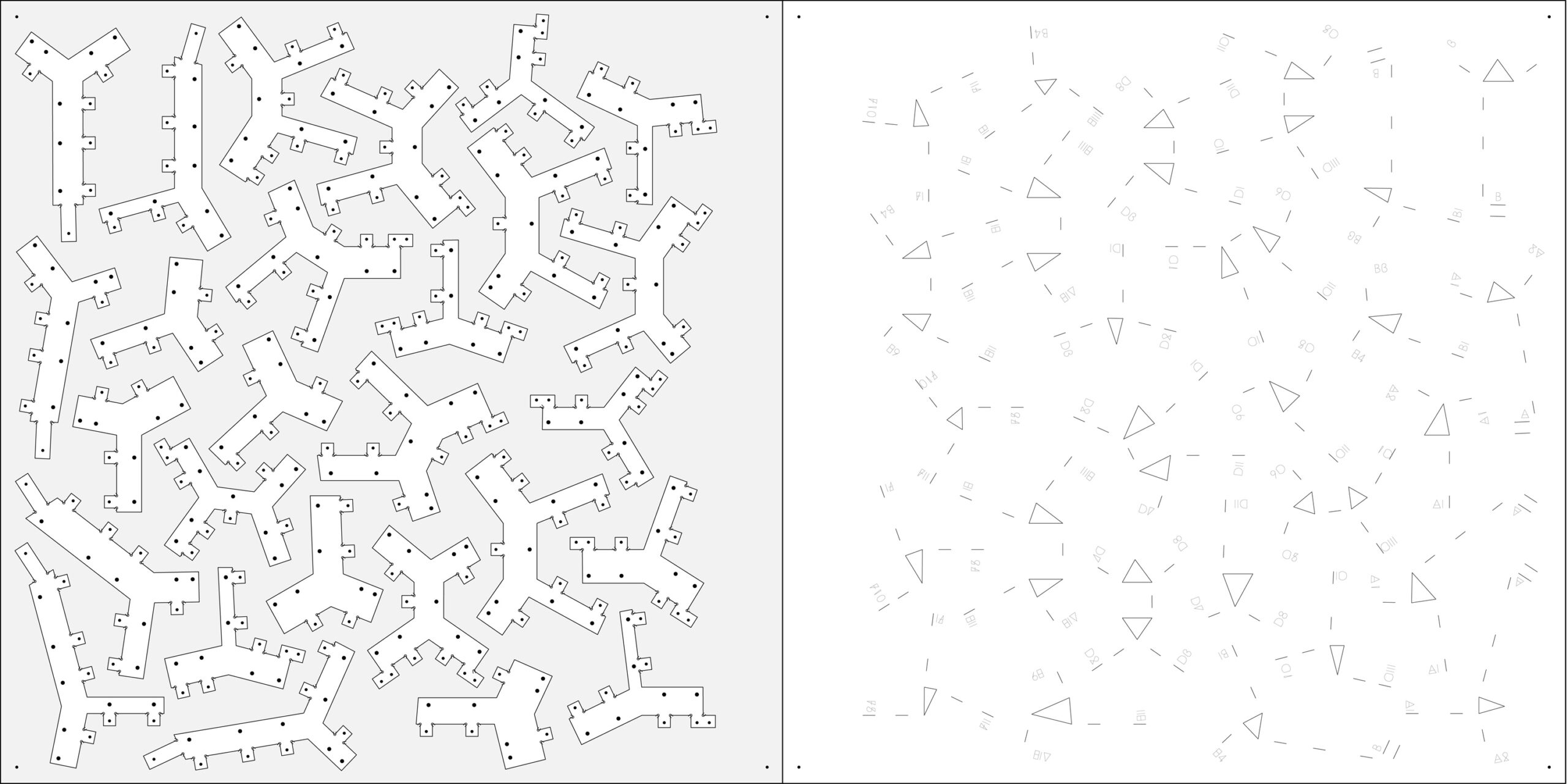

Material exploration was conducted on 0.025″ aluminum as a viable medium to construct the Thornshell, both in terms of scoring thickness for folding, and cutting thickness for creating discrete shapes.

The project was then passed through Mastercam X for machining tolerances and paths, and then again sent to C. R. Onstrud CNC and waterject router machines to create the final cutsheets for production.

Project Materials:

- .025” Aluminum

- Plywood base, supporting legs

- Aluminum rivets