Background

Designed and built as a passion project, the Athene keyboard aims to offer a typing experience that excels in looks, sound, and feel.

Role

Product Designer, Electrical Engineer, Product Visualizer – solo project

Tools

Autodesk Fusion 360, KiCad, Keyshot, Blender, Adobe Photoshop, Adobe Illustrator, Git + Github

Project Timeframe

6 months

Project context and scope

During 2020, I had a strong desire to build and create my own custom keyboard. Not satisfied with the keyboard options readily available, and with a strong desire to dive into human-computer interaction design, I set out to build my own dream peripheral.

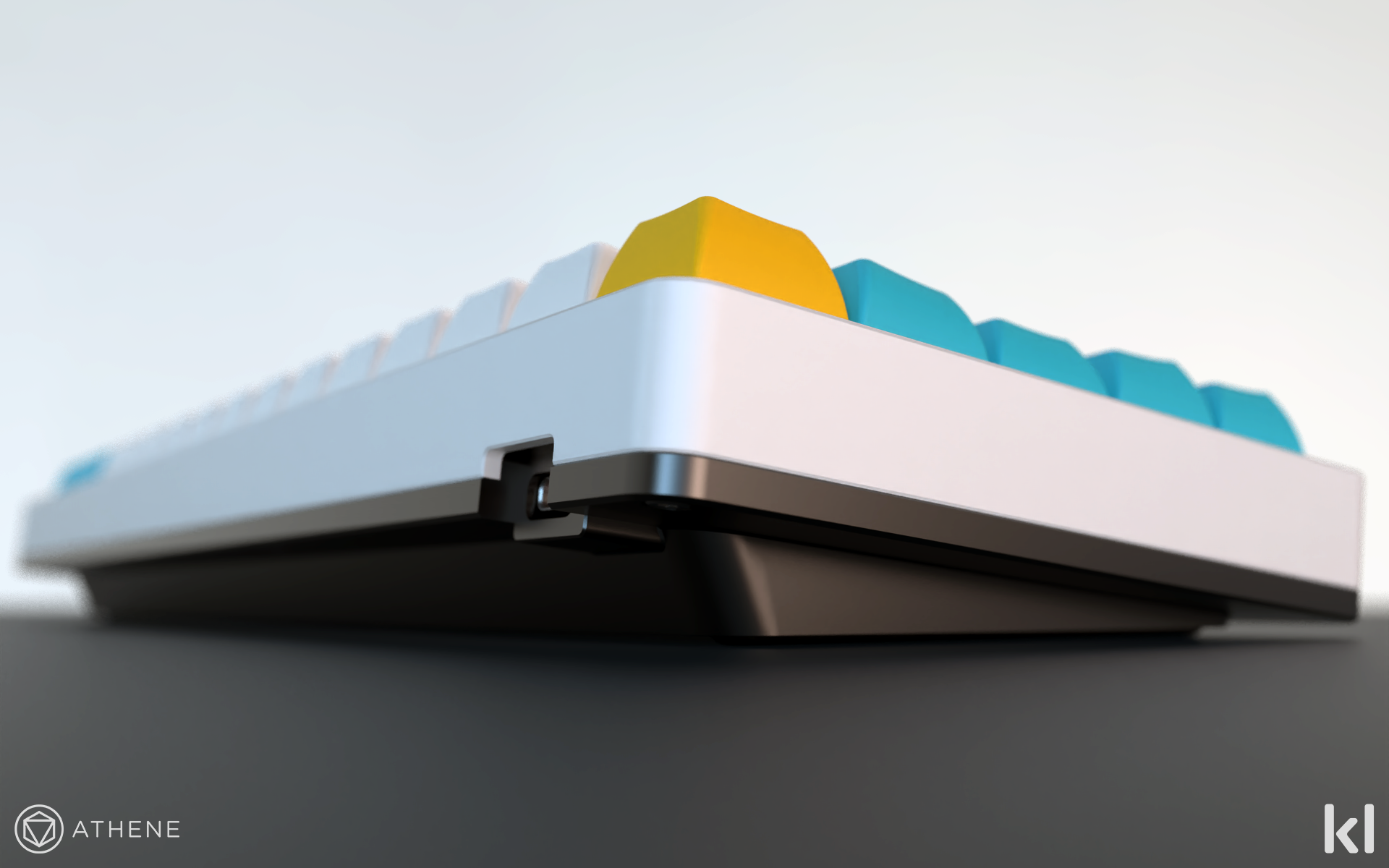

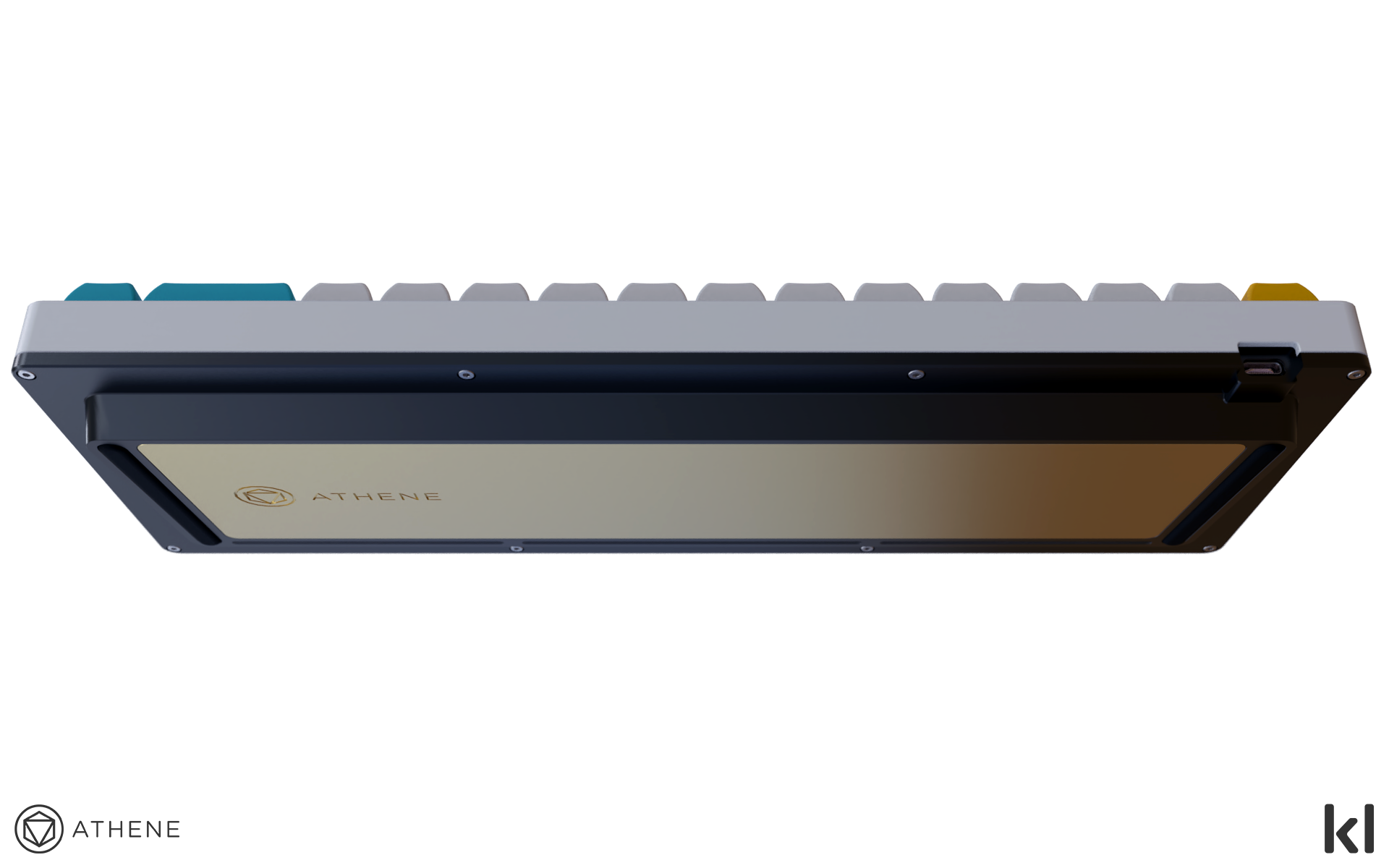

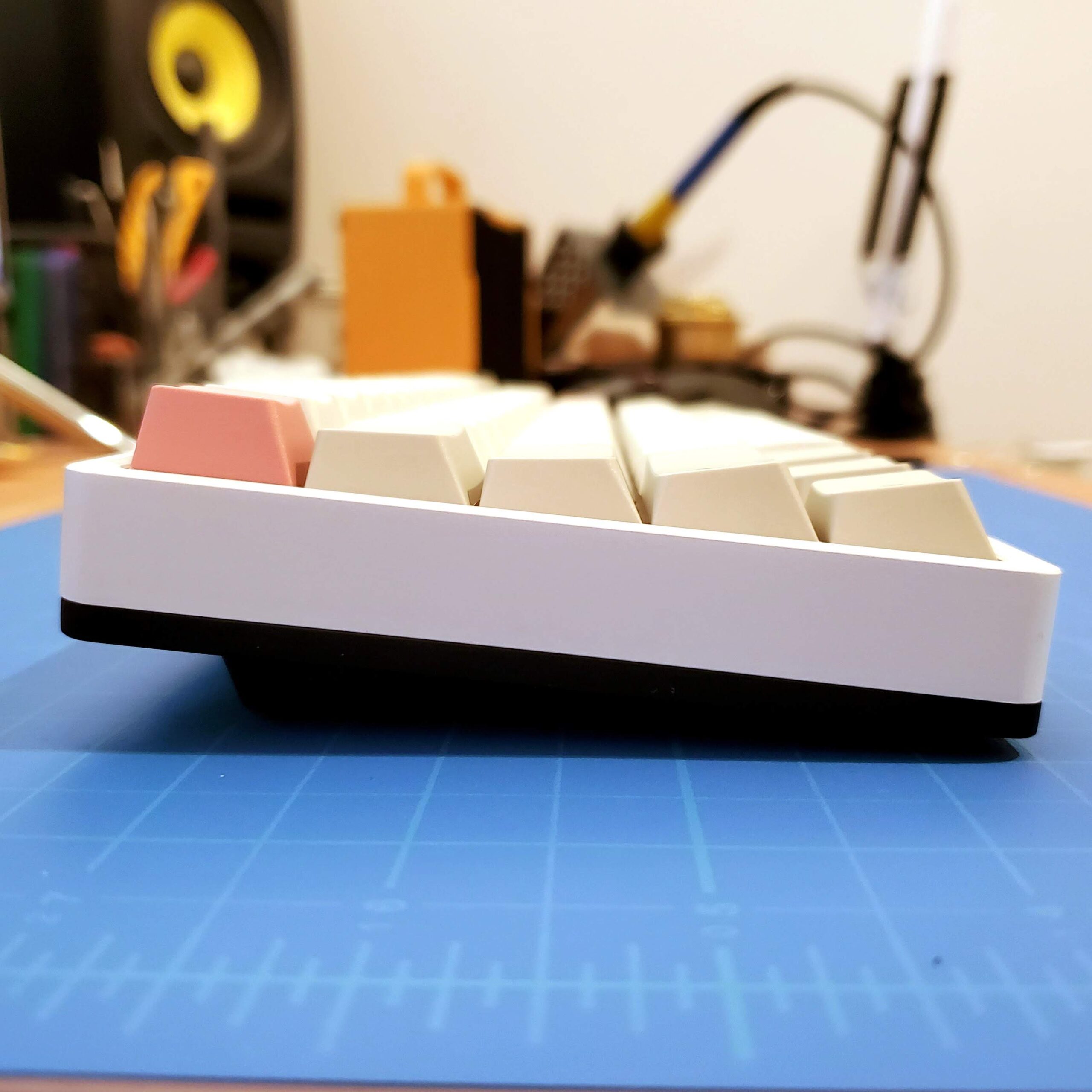

Refined through numerous design iterations and continuous feedback from the keyboard community, the Athene keyboard was created to suit my own aesthetics and use case. With its timeless & minimalistic apperearance, the keyboard features a solid CNC aluminum frame, decoupled gasket mounting system, premium brass weight, RGB backlighting, and hotswap switch compatibility… all powered by USB-C on open source QMK software.

Research & Development

Development of the Athene was multi-faceted, and encompassed 4 key areas that combined together, would result in a completed product. As this was a solo project, I had the opportunity to leverage my talents to work on all of these areas of study.

- Case Design – The physical product specifications. Aspects include material selection, respecting manufacturing tolerances, product visualization, and overall look and feel of the keyboard.

- PCB Design – The circuitboard that powers the keyboard. Aspects include parts specifications and availability, circuit routing, and PCB fabrication

- Firmware compatibility – The software link that turns presses into letters on the computer. Aspects include firmware specifications, coding, and flashing microcontroller chips with compatible code.

- Manufacturing – The suppliers and manufacturers needed to turn a design idea into reality. Aspects include reaching out to qualified manufacturers that are reliable, have quick turnarounds, and able to produce the end product.

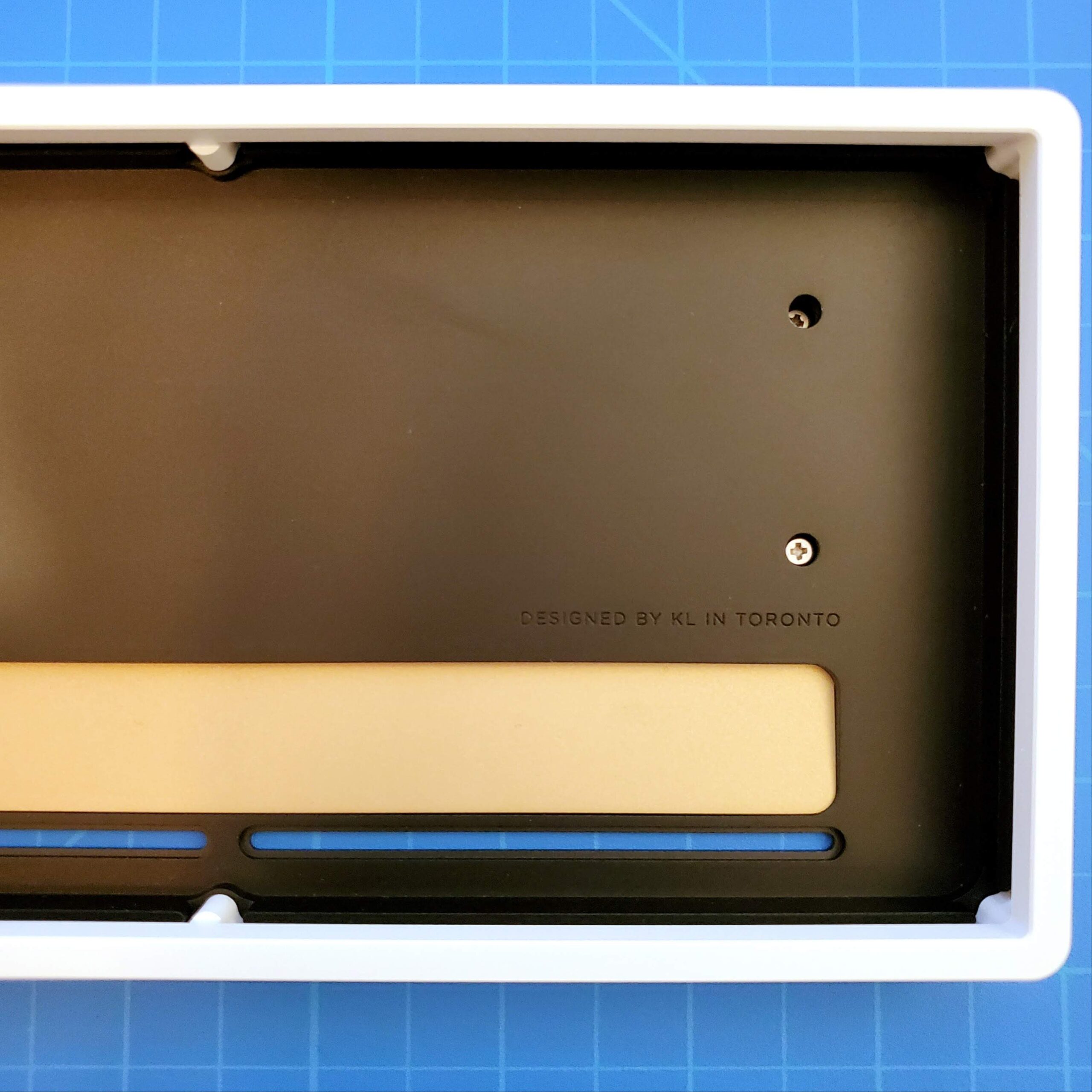

Case Design

Shaping the physical product

The case was primarily designed in Autocad Fusion 360, based on important part specifications such as the standard size of computer keycaps, keyswitch dimensions, and desired keyboard angle & layout.

Material sample testing and experimentation was key in picking out the ideal material for the keyboard. In collaboration with manufacturing, CNC aluminum type 6061 was picked as the primary case material and keycap plate. Usability feedback and material preference was gathered from several different user groups in dedicated keyboard communities as well as through real life feedback.

Product Visualizations

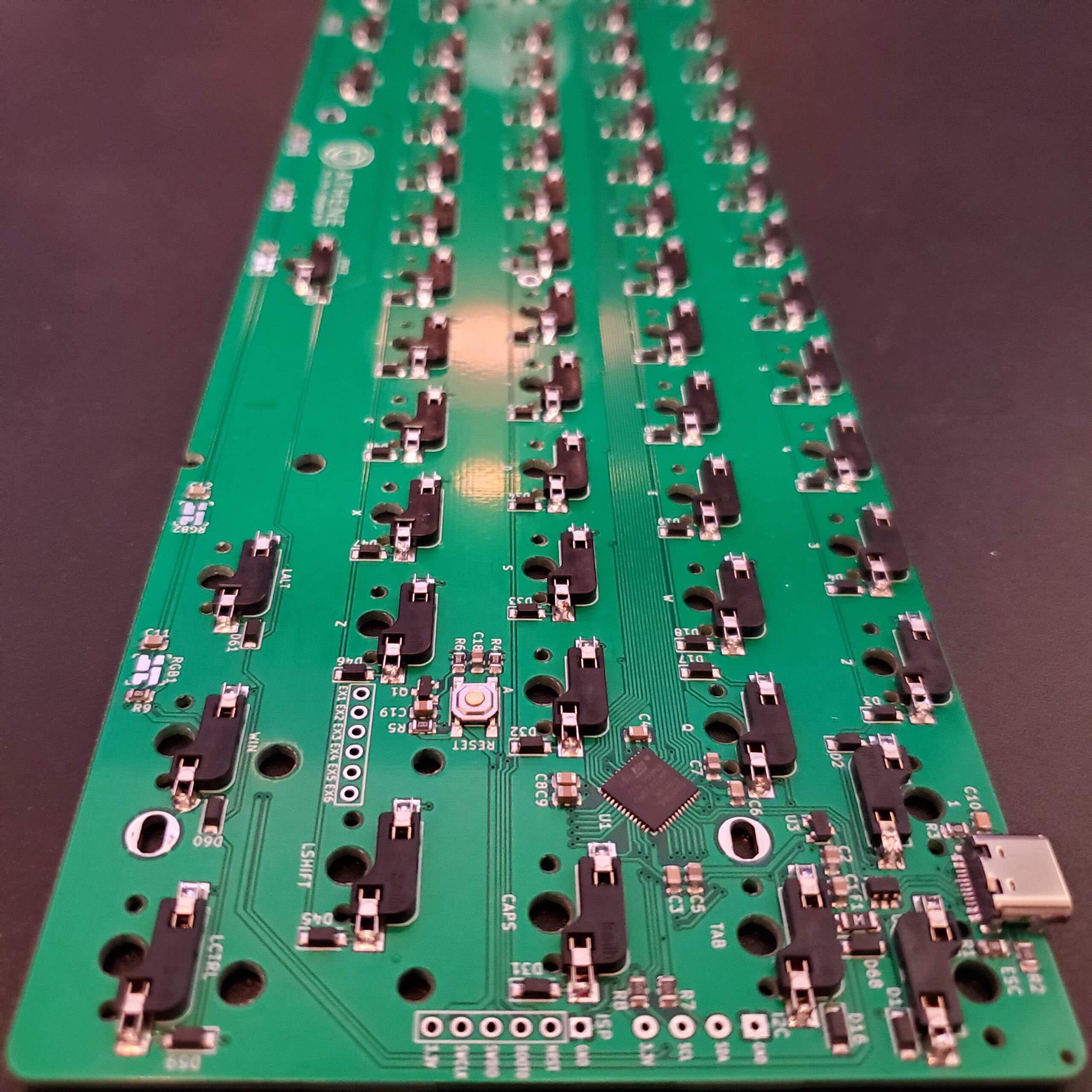

PCB Design

Powering the electrical circuitry

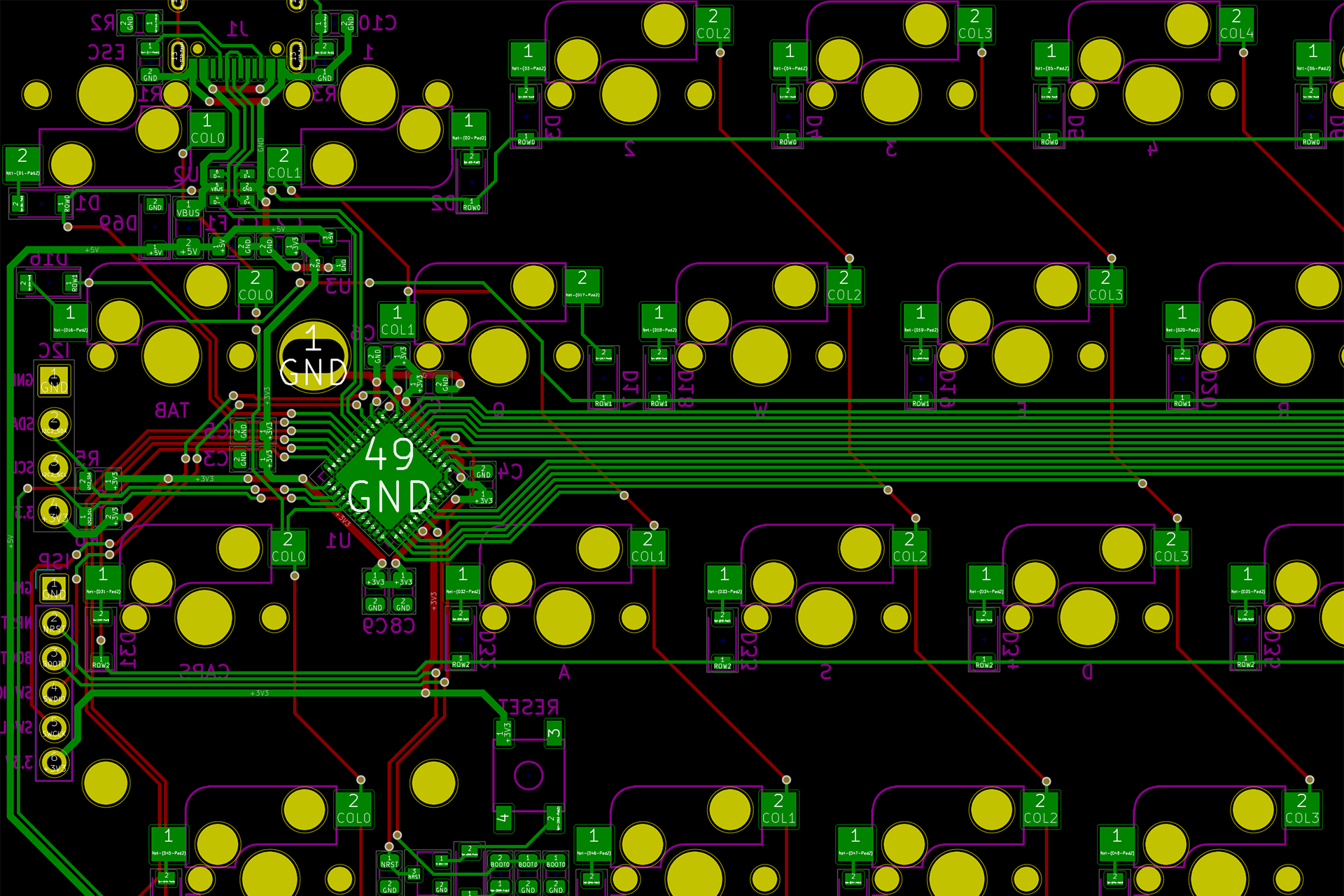

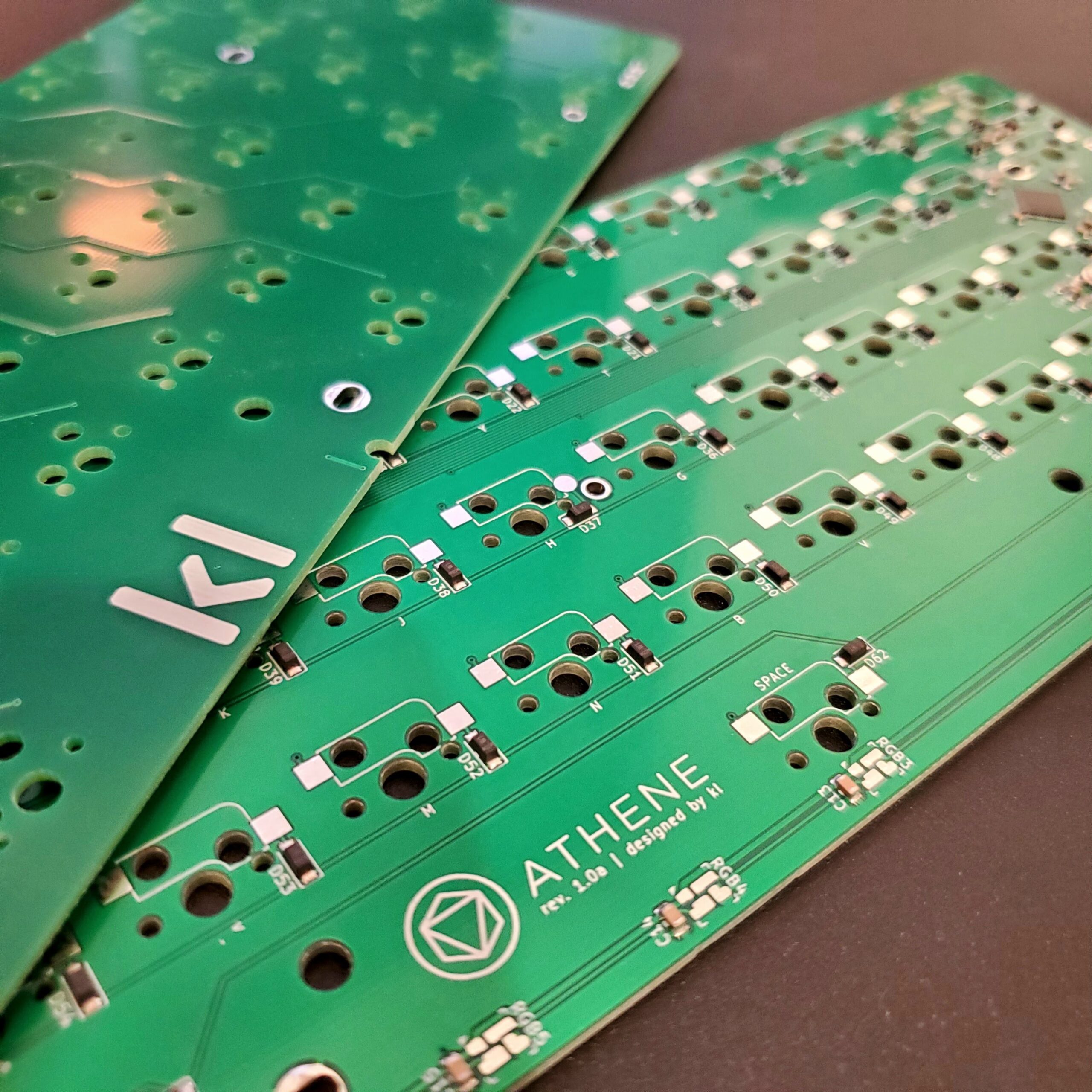

The PCB design and documentation was done primary in KiCad. The final production design was a 2-layer PCB with mostly standard SMT (surface mount) pick-and-place components, aside from the hotswap keyswitch adapters.

An important part of the design process was referencing part documentation, as well as following best practices for PCB routing, acceptable tolerances, and voltages.

The layout of the PCB was also reviewed against open-source documentation of other built keyboards, and revised rigourously before PCB manufacturing to ensure compliance and robustness.

Documentation of the circuitry was also created to ensure that the designs are replicable and scalable during production.

PCB Samples

Final Product

Product Features

- Gasketed plate mount system that runs along all sides of the keyboard, providing a fully decoupled system for ideal sound isolation.

- CNC-machined 6061 alloy anodized aluminum body with slim rounded bezels provides a sleek aesthethic and refined feel.

- 6-degree typing angle provides a slight natural incline suitable for users.

- Lasercut 1.5mm thick aluminum or brass mounting plate offers choice of different typing feel and looks.

- Solid brass bottom case weight for additional dampening and premium construction.

- Foam sublayer between the PCB and bottom case further cancels out excessive vibrations and echoing.

- Custom-designed QMK-compatible PCB board.

- Case design is also compatible with existing TADA68/TOFU65 PCB’s, offering an upgrade path for existing keyboards.

Specifications

- Dimensions: 316mm x 106mm (WxL), 20-31mm (Front to Rear bezel height)

- Plate Material Options: Aluminum, Brass

- Layouts Supported:

- Hotswap: ANSI

- Soldered: ANSI, ISO, Split backspace, Split L/R Shift, Split Space